ASEMindtec

for Industrial Inspection

Non-destructive detection of internal degradation in steel

- Detect changes via piezoelectric and magnetostrictive effects

- Assess corrosion, embrittlement, residual stress

- Applicable to various materials and fields

Application Fields

Expected Areas of Application

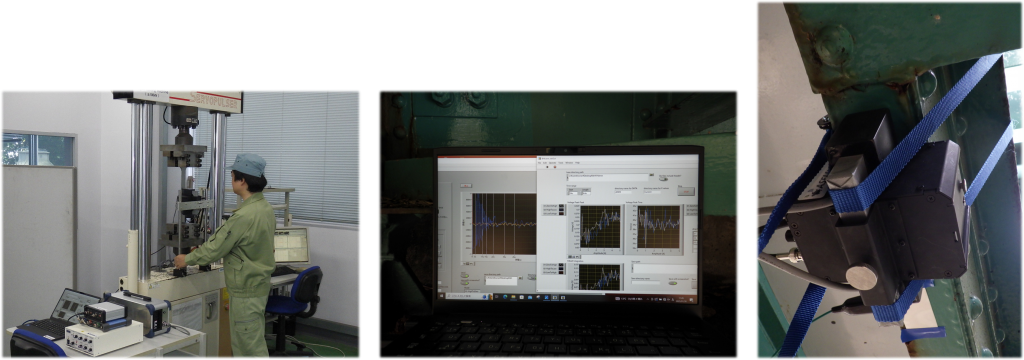

ASEM Implementation Example

As part of a pilot initiative to evaluate the condition of bridge structures, IHI Inspection & Instrumentation Co., Ltd. (IIC) has introduced an industrial non-destructive inspection system (ASEMindtec).

The system is based on ASEM (Acoustically Stimulated Electromagnetic Method) technology, which enables visualization of the internal electromagnetic state of steel without removing surface coatings. This allows for the detection of deterioration and stress changes beneath coatings—challenges that conventional non-destructive methods have struggled to address—thus contributing to more advanced infrastructure maintenance. IIC is currently conducting on-site validation trials to assess the effectiveness of ASEM-based inspection under real-world conditions

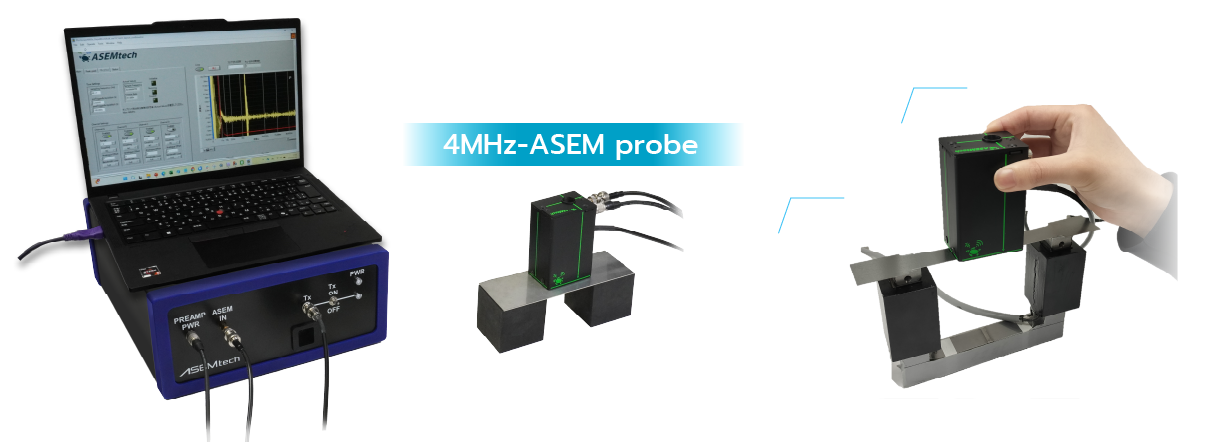

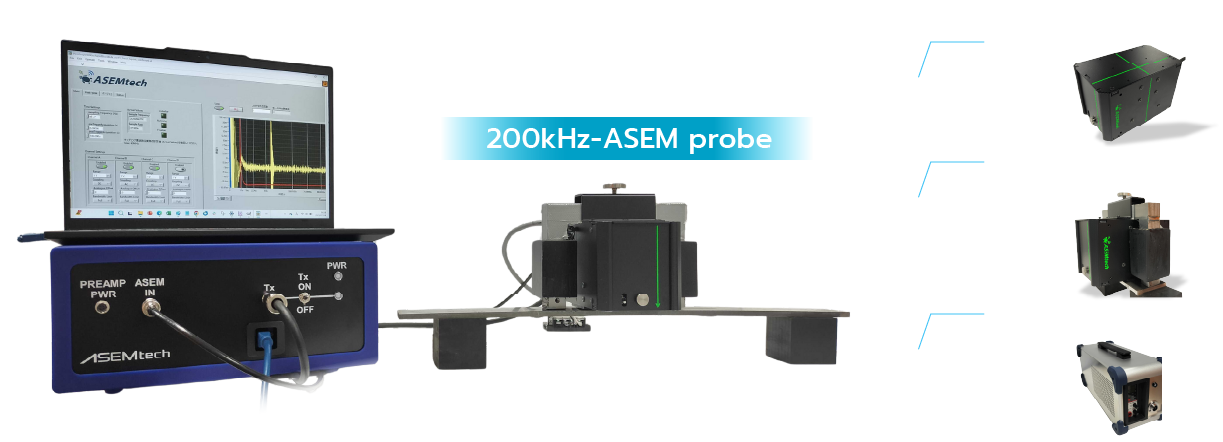

System Setup

ASEM detects material degradation and property changes through variations in piezoelectric and magnetostrictive effects. It may enable evaluation that was previously deemed impossible.

System specifications can be customized based on intended use.

Examples: corrosion, deformation, embrittlement, residual stress, metal fatigue, and material inhomogeneity invisible to the eye.

| Product name | Configuration | Overview | |

|---|---|---|---|

| Standard system | ASEM probe |

・Dedicated US transducer ・Receiving Antenna ・Pre-amplifier |

Frequency:200kHz~10MHz Focal spot size:30mmφ~1mmφ (as requested) Compact design Software: RF waveform, envelope waveform, integration function, derivation of basic parameters |

| Measurement platform |

・Pulser/Receiver ・AD converter ・Post amplifier ・Low-noise power supply ・Software (Installed on a dedicated PC) |

||

| Option | ― |

・Scanning and imaging ・Magnetic-field application ・Analysis software ・Integration with other devices, etc. |

We can meet your needs. |

(Magnetic signals increase in areas where wall thinning has occurred.)

(Magnetic signals become weaker in areas where residual stress remains.)

200kHz-ASEM System

- For infrastructure and large component inspection

- Capable of measurement through paint

- Ultrasound irradiation spot: approx. 30 mmφ

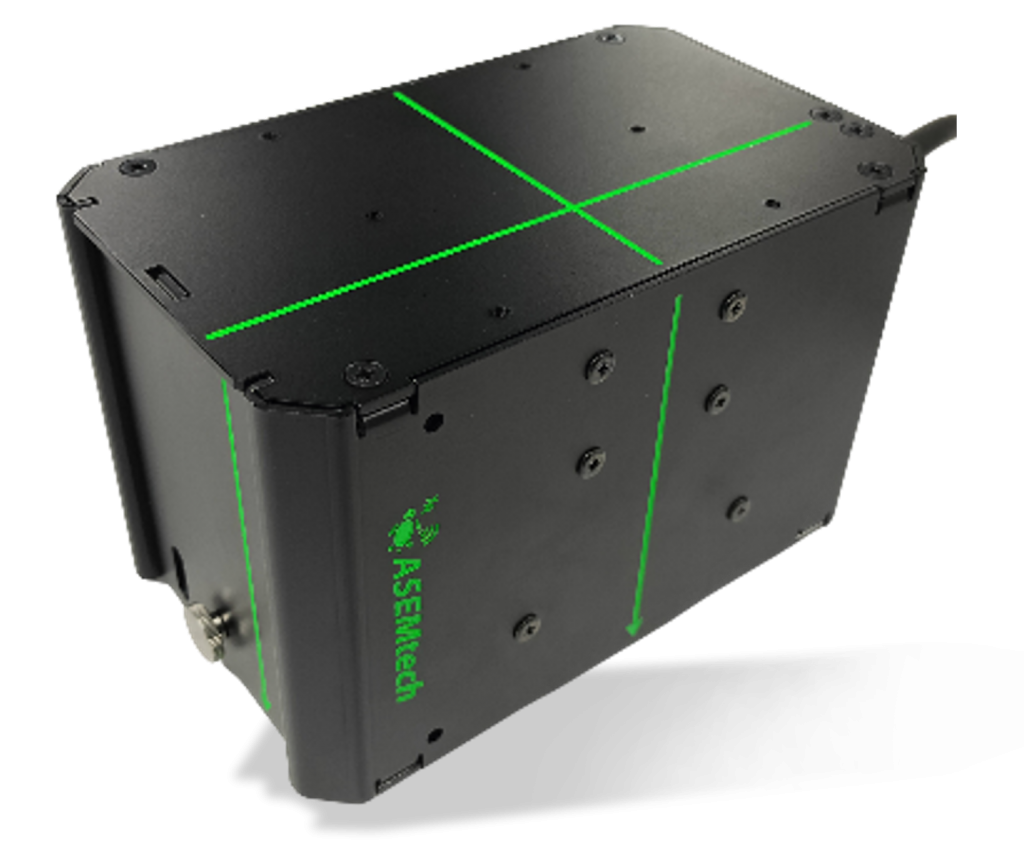

4MHz-ASEM System

- For precision inspection of steel plates, etc.

- Optional scanner enables imaging

- Ultrasound focal spot: approx. 2 mmφ