ASEM Case Studies

ASEM implementation in industrial sectors

Case Study 1: Bridge Structural Inspection

As part of a pilot initiative to evaluate the condition of bridge structures, IHI Inspection & Instrumentation Co., Ltd. (IIC) has introduced an industrial non-destructive inspection system (ASEMindtec).

The system is based on ASEM technology, which enables visualization of the internal electromagnetic state of steel without removing surface coatings. This allows for the detection of deterioration and stress changes beneath coatings—challenges that conventional non-destructive methods have struggled to address—thus contributing to more advanced infrastructure maintenance. IIC is currently conducting on-site validation trials to assess the effectiveness of ASEM-based inspection under real-world conditions

Case Study 2: Weld Joint Inspection

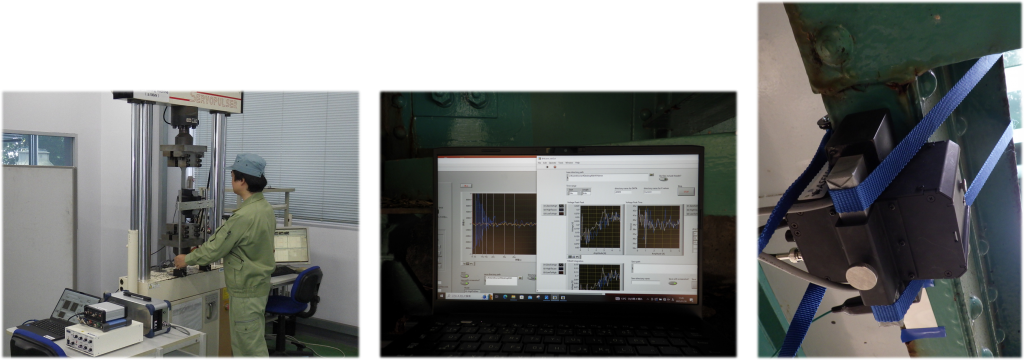

The ASEM method enables non-destructive and straightforward evaluation and imaging of the magnetic properties of steel materials. It has been applied in studies investigating compositional changes and residual stress assessment in steel.

- IEEE T-UFFC 67, 825 (2020): Tensile-stress Dependence of Magnetic Hysteresis Properties Measured by the Acoustically Stimulated Electromagnetic Response in Steel.

- IEEE T-UFFC 69, 1478 (2022): Evaluation of Tensile Residual Stress in Welded Steel Plates Using Acoustically Stimulated Electromagnetic Response.

In response to a request from a major manufacturing company, we conducted an evaluation of welded test specimens prepared by the company.

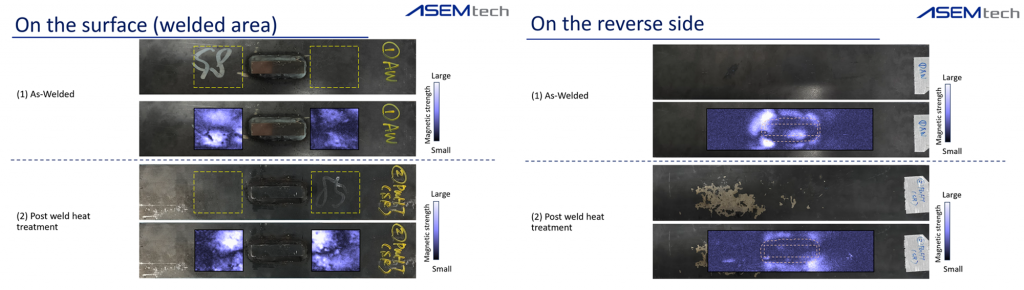

ASEM imaging visualizes magnetic field distributions, reflecting contributions from both thermal-induced magnetic changes—such as phase transitions and grain size variations—and stress-induced magnetic changes associated with residual stress. Measurements were conducted with mill scale remaining on the surface, and its influence was found to be negligible. This confirms that steel evaluation can be performed without surface treatments such as polishing.

On the surface (welded area), complex magnetic distributions were observed in both (1) As-welded and (2) Post weld heat treatment. These patterns are primarily attributed to compositional changes in the steel induced by heating and cooling processes. This indicates that welding induces non-uniform compositional changes in the steel surrounding the weld area, and that such changes are not necessarily eliminated by post-weld heat treatment aimed at stress relief.

On the reverse side, magnetic changes were observed surrounding the welded area, with a tendency toward homogenization of the magnetic distribution following post-weld heat treatment. This suggests that ASEM imaging on the reverse side corresponds to the distribution of residual stress. Moving forward, we aim to evaluate changes in steel properties induced by welding from a novel perspective, establish methods for identifying optimal welding conditions, and develop approaches for predicting failure risks in welded regions.

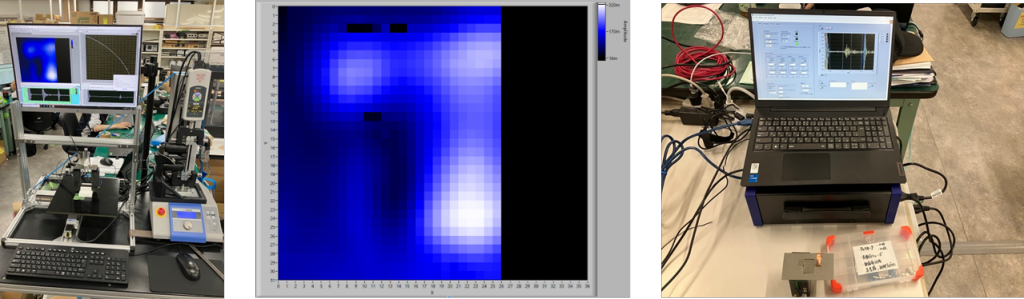

Case Study 3: Evaluation of Electromagnetic Steel Sheets

Denshijiki Industry Co., Ltd. (EMIC – Electronic Magnetic Industry), a leading company in the field of magnetic applications, has adopted ASEMtech’s industrial non-destructive inspection system, ASEMindtec, for the evaluation of electromagnetic steel sheets.

By leveraging the unique capabilities of ASEM technology to visualize the spatial distribution of local hysteresis loops, the company is exploring quantitative assessments of magnetic property changes caused by processing and heat treatment.

Through the integration of EMIC’s advanced expertise in non-destructive testing and magnetic measurement with our sensing technology, we aim to deliver new value across a wide range of industries, including automotive, railway, home appliances, and steel manufacturing.